/

CNC fabrication

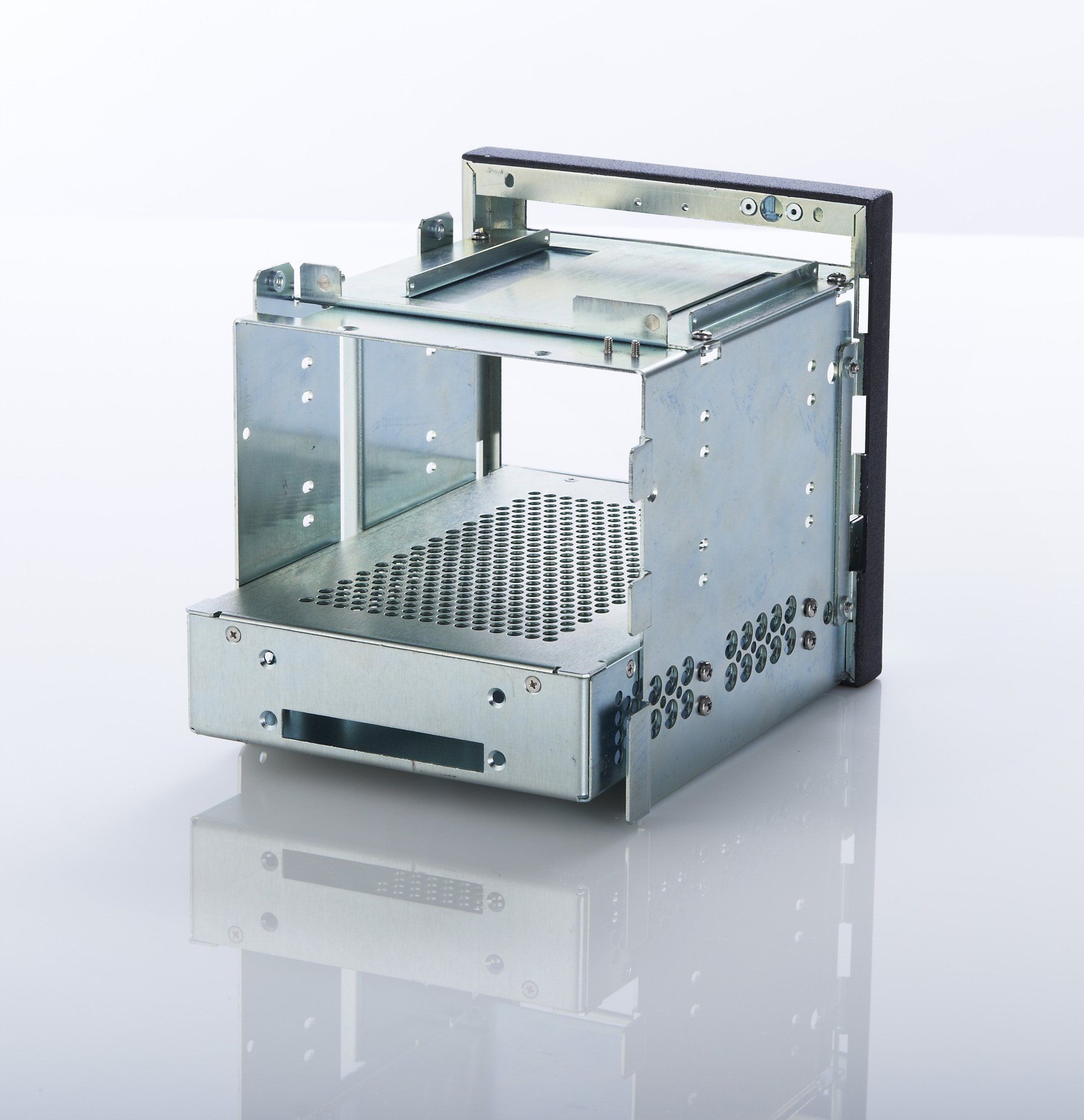

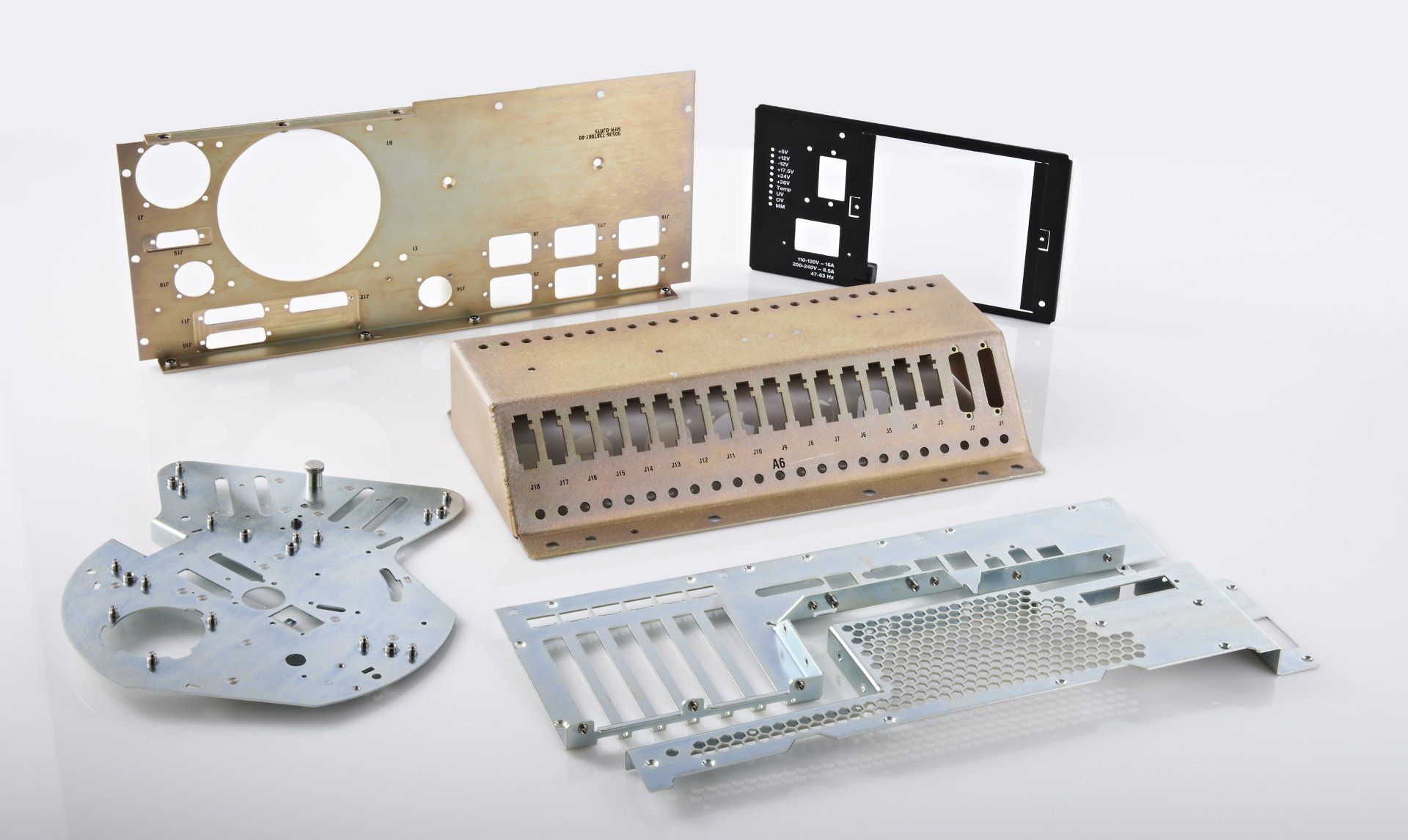

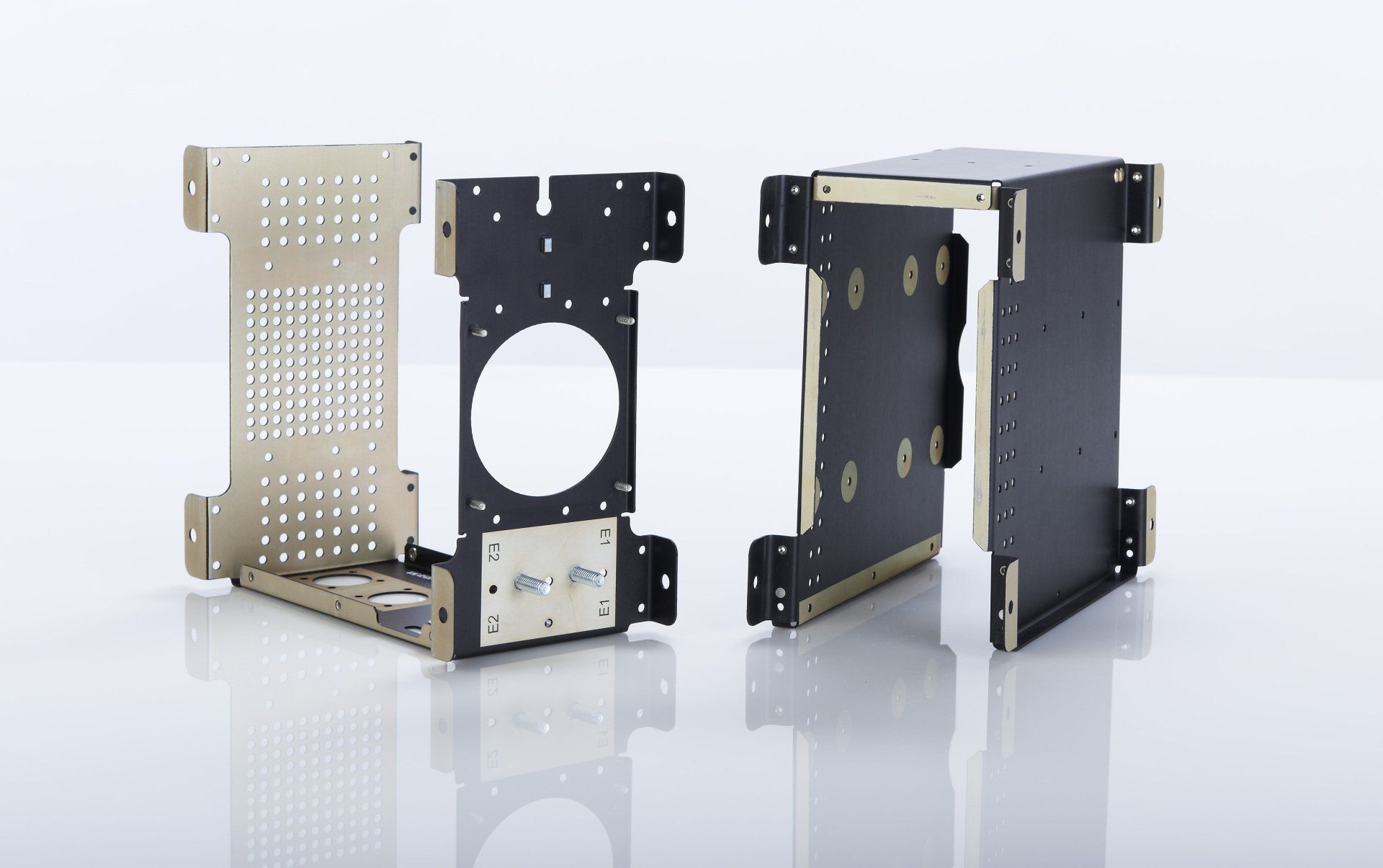

our Metal Fabrication Department produces component parts from prototype through production.

We proudly offer world-class manufacturing and quality products based on our 30+ years of industry expertise in tool and fixture design, stamping, CNC punching and forming, laser processing of sheet, plate and tubing, welding, and light assembly. We work closely with our quality-approved vendors to provide outside services such as painting, powder coating, plating, heat treating, and silk screening.

We deliver value to our customers by offering design assistance and, in many cases, providing total project management including mechanical testing and warehousing for just-in-time deliveries. We work with many material types including steel, aluminum, stainless steel, copper, brass, and plastics.

Pequot Manufacturing has time and again been able to prototype kiosks and other large sheet metal assemblies in two weeks and then shift to a production rollout in another 4 weeks all while maintaining a normal production flow for many other customers with minimal disruption.

| stamping/fabricating |

|---|

| Laser processing up to 60” x 120” x ¾ ” |

| Punch presses up to 120 ton |

| CNC punching up to 60” x 120” x 1/4” |

| CNC forming up to 120” |

| Spot welding up to ⅛" Aluminum |

| MIG, TIG and Robotic welding |

| Hardware insertion & assembly |